PVC CPVC Soil Extrusion Bututu

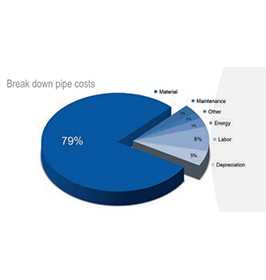

Maganin Ajiye Kuɗi

1. Kai tsaye Ƙara - CaCO3

2. Raka'a kula da bango (scanners)

3. Cibiyar Zazzagewa ta atomatik (ATC)

4. Tsarin Gravimetric (RGS)

SUPX Kai tsaye Ƙara - RDA

RDA yana tabbatar da cewa ƙari na kayan zuwa pvc foda za a yi shi a daidai kuma daidaitaccen hanya.An ɗora naúrar RDA a kan extruder don ci gaba da yin allurai na wuyar sarrafa kayan a cikin yanayin masana'antu.Ana iya ƙara yawan adadin CaCO3 ba tare da matsalar rarrabuwa ba.Za a iya shigar da raka'a da yawa don ƙarawa da samar da mafi kyawun sassauci don samarwa.

Amfanin tsarin RDA

• Babu rabuwa na CaCO3 da PVC yayin sufuri.

• Bututu mai laushi.

• Haɗuwa da tanadin makamashi.

• Ƙara sassauci na layin extrusion (tsarin tushe).

• Bugu da kari gravimetric na additives.

• Babban abubuwan fitarwa a ƙananan ƙima.

Rukunin Kula da bango - Masu dubawa

Sarrafa ma'auni na bututu a lokacin samarwa shine muhimmin mahimmanci don kiyaye bututun a cikin ƙayyadaddun da aka fi so. Masu binciken suna iya auna girman bangon bututu da diamita.Akwai kewayon na'urorin daukar hoto tare da fasali daban-daban, suna rufe girman bututu daga 10-1600 mm (1/2 "- 60") diamita.

Amfanin na'urorin binciken mu:

• Ci gaba da kaurin bangon layi da auna diamita

• Mafi ƙarancin kauri na bango (rage kiba)

Cibiyar Zazzabi ta atomatik - ATC

ATC yana ba da damar sarrafa rarraba kauri na bango.ATC na iya daidaita bambance-bambance a cikin kauri na bango kuma don haka rage lokacin farawa layin samarwa, kiba na bututu da tarkacen kayan.

Tsarin Gravimetric - RGS

Babban ɓangaren RGS shine hopper mai aunawa.Bayan an cika shi, kayan yana gudana daga ma'aunin ma'auni a cikin extruder.Rashin nauyi a kowace naúrar lokaci daidai yake da kayan cin abinci na extruder.An kwatanta fitar da fitarwar da aka samu zuwa ƙimar ƙima da aka saita kuma tsarin sarrafawa zai daidaita saurin ƙullewar extruder (ko saurin dosing) don kawo fitarwa zuwa matakin da ake so.Wannan sarrafawa yana kiyaye fitar da fitar da fitar da kyar duk da sauye-sauye a yawan yawan albarkatun kasa.

Maimakon sarrafa fitarwa, ana iya amfani da siginar fitarwa don sarrafa saurin kashewa.A wannan yanayin ana kiyaye nauyin bututu a kowace mita a daidai matakin.Lokacin da layin ya haɗa na'urar daukar hoto na ultrasonic, ana amfani da kayan da aka auna don daidaita ma'aunin ultrasonic ta atomatik.Wannan yana kawar da hanyoyin daidaitawa da hannu.

Tsarin Gudanar da Tsari - PCS II

PCS II kanta tsarin sarrafawa ne wanda za'a iya haɗa shi da ana'urar daukar hotan takardu, ATC, RDA, da RGS.Nau'in na'urar daukar hotan takardu, ATC datsarin gravimetric ya dogara da layin extrusion.

Amfanin hanyoyin ceton kuɗin mu

• Kyakkyawan dawowa kan zuba jari

• Rage lokacin farawa da gogewa

• Mai amfani sada zumunci dubawa domin jimlar extrusion line iko

• Rage kiba

Ana iya amfani da kayan aikin da ake dasu.